Nicotine Extraction

Primary source of high-purity nicotine

Cigarette & Cigar Flavors

Enhances distinctive flavor of tobacco products

Biotechnology Research

Used in developing new pharmaceutical and agricultural products

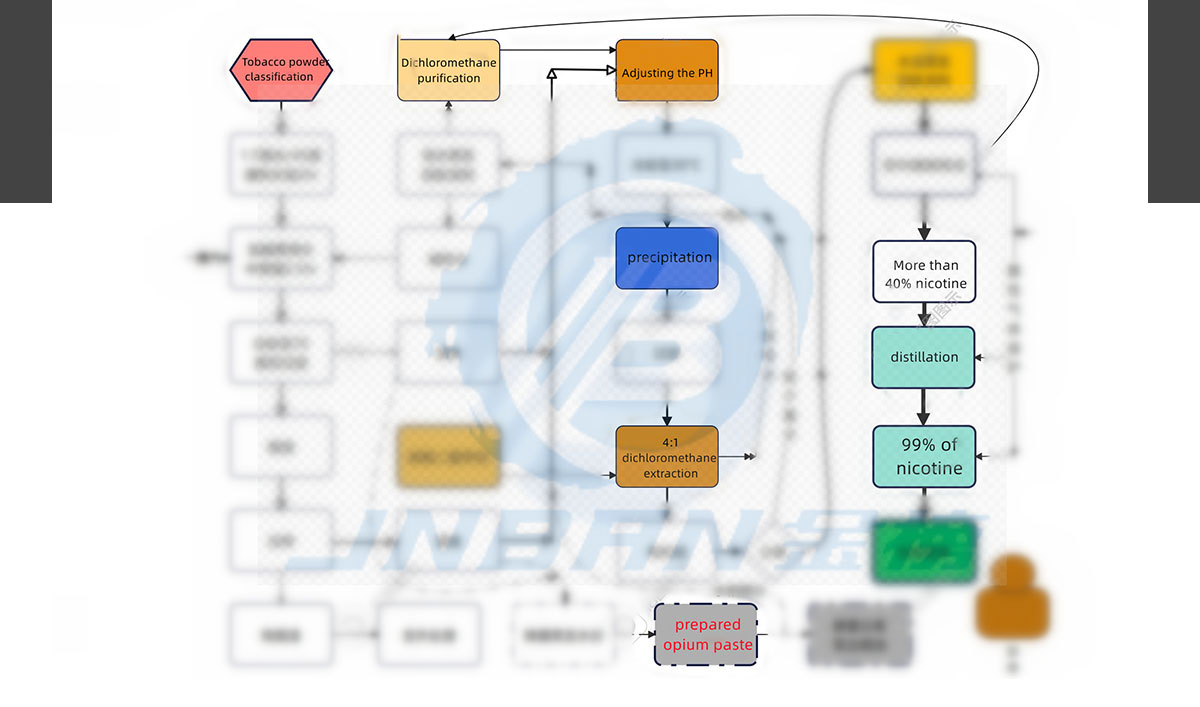

Primary Tobacco Processing

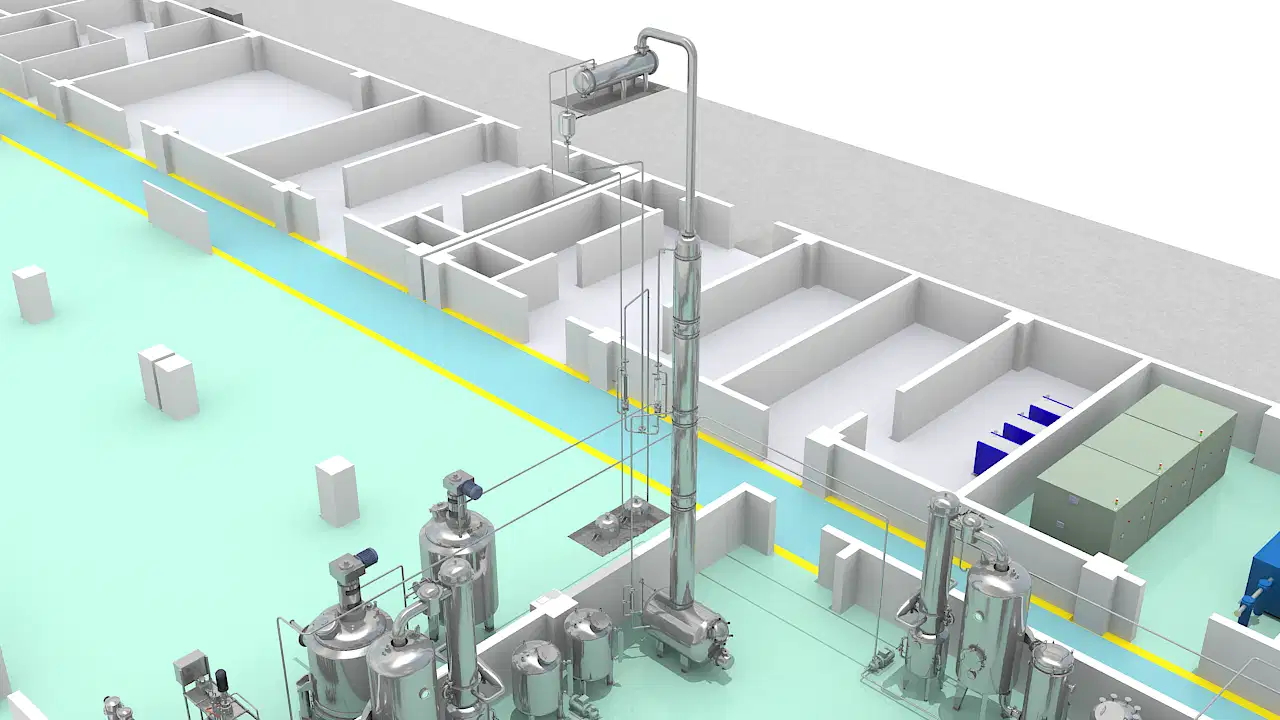

Solvent Extraction

Filtration and Separation

Concentration

Final Packaging

Tobacco leaves are crushed and screened to remove impurities.

Environmentally friendly solvents are used to extract active components from tobacco through soaking or dynamic extraction.

Multi-stage filtration removes suspended solids to ensure the purity of the extract.

Low-temperature vacuum concentration equipment is used to reduce heat exposure and preserve active ingredients; high-quality tobacco paste is obtained using a vacuum belt dryer.

The tobacco paste undergoes quality testing before entering standardized packaging for convenient storage and transportation.

-01

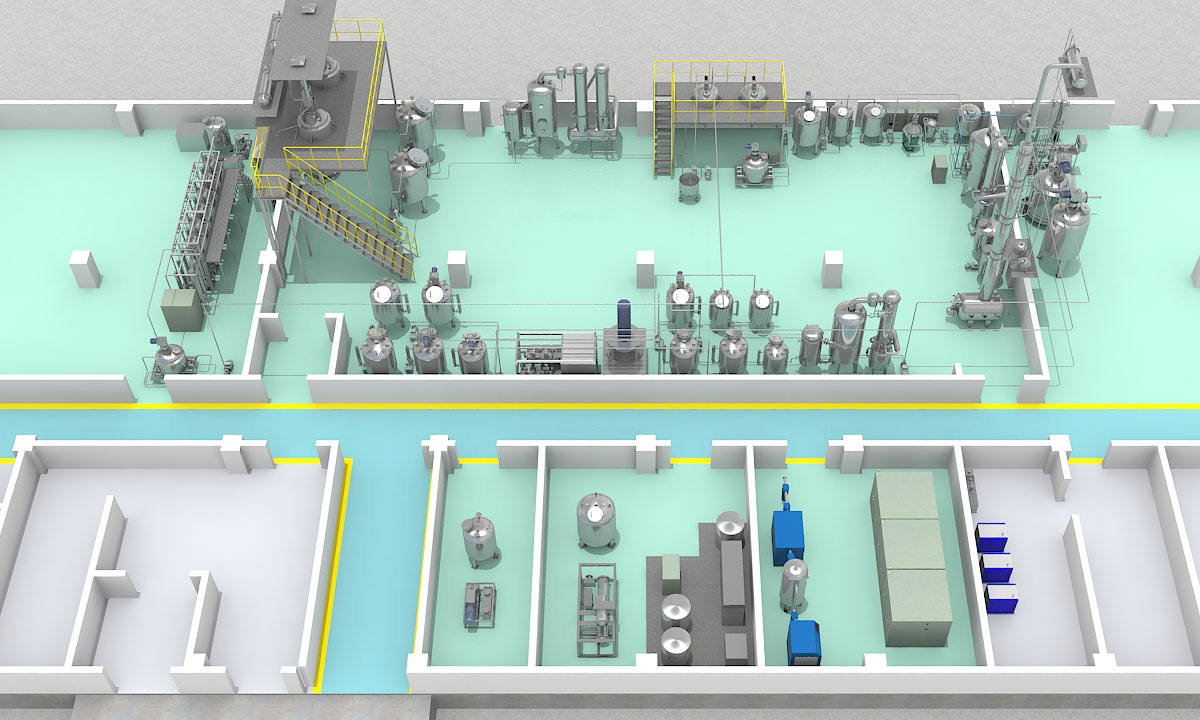

High-Efficiency Extraction Technology

Precise control of extraction temperature and solvent ratio to maximize active ingredients.

-02

Low-Temperature Vacuum Concentration

Protects active components in tobacco and ensures product quality.

-03

Intelligent Production Control

Precise control of extraction temperature and solvent ratio to maximize active ingredients.

-04

Energy-Saving and Eco-Friendly Design

Energy-efficient operation, compliant with international environmental standards, and equipped with advanced waste gas/liquid treatment technology.

| Model | Capacity(kg/Batch) | Extraction Time(h) | Concentration Temperature(℃) |

| JBYC-100 | 100 | 4-6 | 45-90 |

| JBYC-500 | 500 | 4-6 | 45-90 |

| JBYC-1000 | 1000 | 4-6 | 45-90 |

| JBYC-3000 | 3000 | 4-6 | 45-90 |

Multi-functional Extraction Tank

This equipment is suitable for normal pressure, pressurized, water decoction, warm soaking, hot reflux, forced circulation, percolation, aromatic oil extraction and organic solvent recovery of tobacco leaves, especially the use of dynamic extraction or multi-tank countercurrent extraction, which has better effect, short time and high nicotine content. The tank is equipped with CIP cleaning automatic rotating spray ball, thermometer, pressure gauge, explosion-proof sight hole lamp, sight glass, quick-open feeding port, etc., to ensure easy operation and meet GMP standards.

Solid-liquid reverse continuous extraction unit

The countercurrent extraction unit is a highly efficient solid-liquid separation equipment. Through the countercurrent process, the equipment can maximize the solvent utilization and extraction efficiency while reducing energy consumption and operating costs. Its main features include fully automated control, easy operation, strong adaptability and high stability. It is suitable for the continuous extraction process of tobacco leaves to ensure the consistency of product purity and quality.

Tubular Centrifuge

Used for solid-liquid separation in tobacco paste extraction processes, efficiently separating solid particles from liquid components to improve product purity and quality.

Working Principle

The tubular centrifuge utilizes centrifugal force generated by high-speed rotation to separate solid particles from liquids in a mixture. The specific process is as follows:

Feeding: The tobacco paste mixture is fed into the centrifuge drum through the feed pipe.

Separation: Under high-speed rotation (typically 10,000-15,000 rpm), solid particles are thrown toward the drum wall due to their higher density, while the liquid remains on the inner side.

Liquid Discharge: The separated liquid is discharged through the supernatant outlet.

Slag Discharge: Solid particles accumulate in the drum and are manually or automatically removed after the machine stops.

Concentration Machine

Nicotine concentration equipment is a highly efficient equipment specially used for concentrating and purifying nicotine solution, which is widely used in pharmaceutical and chemical industries. The equipment achieves efficient concentration of nicotine solution through evaporation and condensation process. Its main features include simple operation, high degree of automation, low energy consumption, good concentration effect, etc. The equipment design focuses on corrosion resistance and high temperature stability to ensure that the high purity and quality of nicotine are maintained during the concentration process, providing high-quality raw materials for subsequent processing.

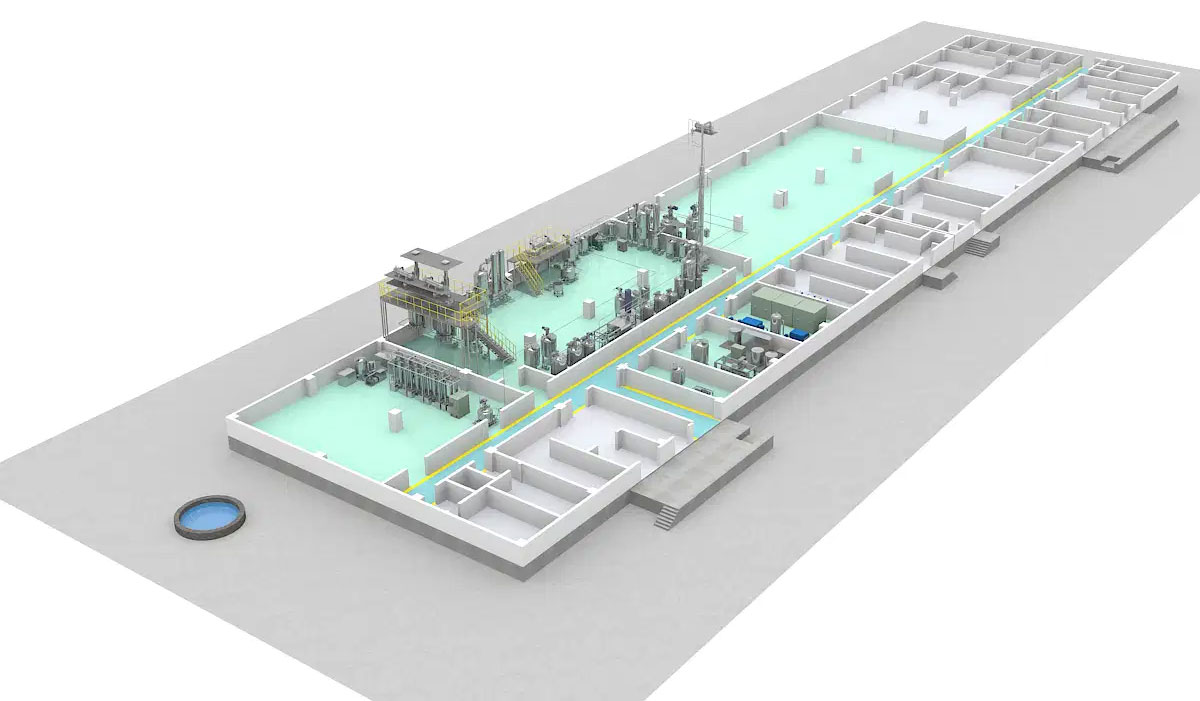

We operate a fully-equipped tobacco paste extraction line with daily processing capacity ranging from 100KG to 50 tons of tobacco leaves, delivering paste with authentic flavor and intact aroma profile.

For tobacco paste extraction, we possess patented technologies and integrated systems including: Extraction System,Blending System, Enzymatic Precipitation System, Concentration System, Filtration System, Utility Engineering System, Automation System, Formulation Management System forming the core framework of our complete production line.

For inquiries regarding tobacco paste extraction:Manager Sun +86-18958768320(WhatsApp)

JNBAN vacuum belt dryers have been included in the“ Eleventh Five-Year National Science and Technology Support Program, Zhejiang Science and Technology Department Major Science and Technology Public Relations Project and Zhejiang Province” Major Science and Technology Special (Priority Theme) Social Development Project. There are 4 papers and 6 patent applications accepted, including 4 invention patents, 2 special authorizations, and 10 practical patents. They won the third prize of Zhejiang Science and Technology Progress Award and the first set of products in Zhejiang Province.……

Wenzhou Jinbang Light Industry Machinery Co., Ltd. is a high-tech enterprise integrating R & D, manufacturing and sales. Professional in the production and sales of pharmaceutical, bioengineering machinery and equipment professional enterprises. The company mainly specializes in consulting, scheme design and manufacturing, budget, on-site installation and after-sale maintenance of traditional Chinese medicine extraction equipment, concentration equipment, separation and purification equipment, alcohol recovery equipment and drying equipment.……

Wenzhou Jinbang Light Ind Machinery Co., Ltd

E-mail: info@jnbantech.com

P.C: 325025

Address: No. 420 Binhai 23rd Road, Binhai Park, Economic & Technological Development Zone, Wenzhou, Zhejiang, China