Automation and digitalization

Equipment

Automation

Process

Automation

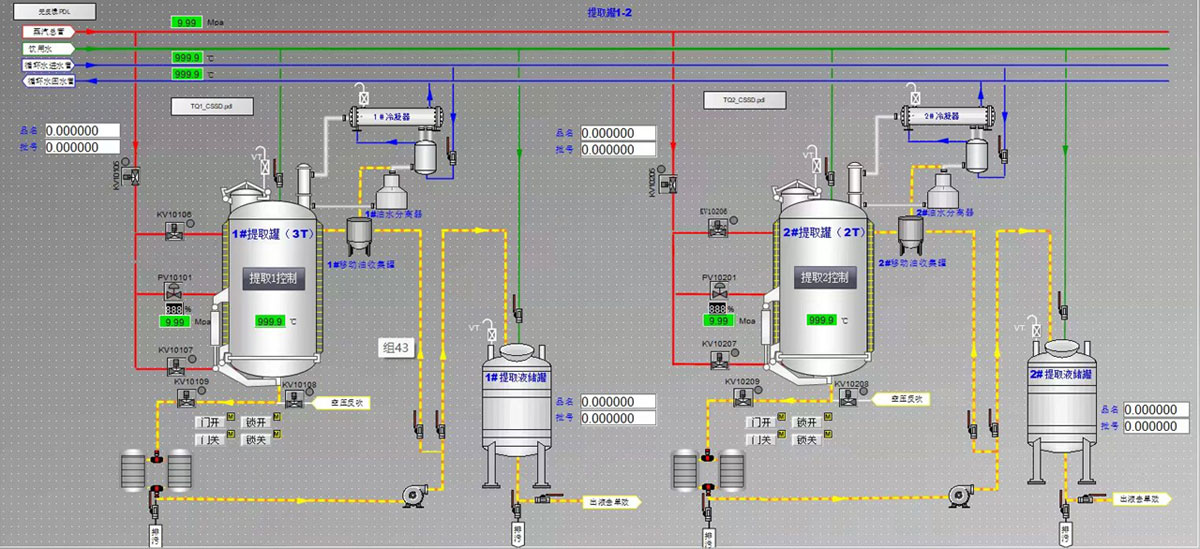

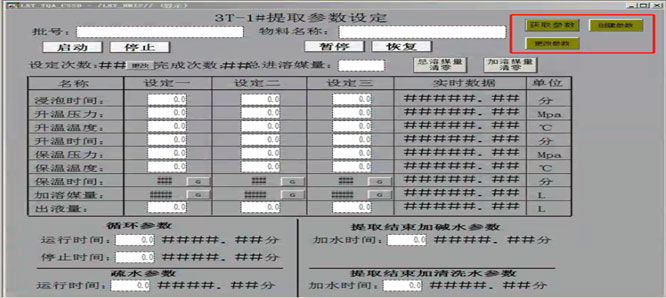

Jinbang provides a variety of integrated DCS automation solutions including DeltaV platform, PCS7 platform, Experion PKS platform, etc., which are used to break the information barriers between devices, centrally manage discrete devices, form a complete device control chain, and realize process automation through overall Batch control + DCS, helping users who want to achieve digital transformation.

Fully compliant with ISA-88 standards

Data centralization

Flexible control improves system risk resistance

With a variety of formulas, flexible deployment combined with process

Fully automated process to reduce losses caused by human errors

Improve the efficiency and stability of production equipment

Process Automation Control Design Principles

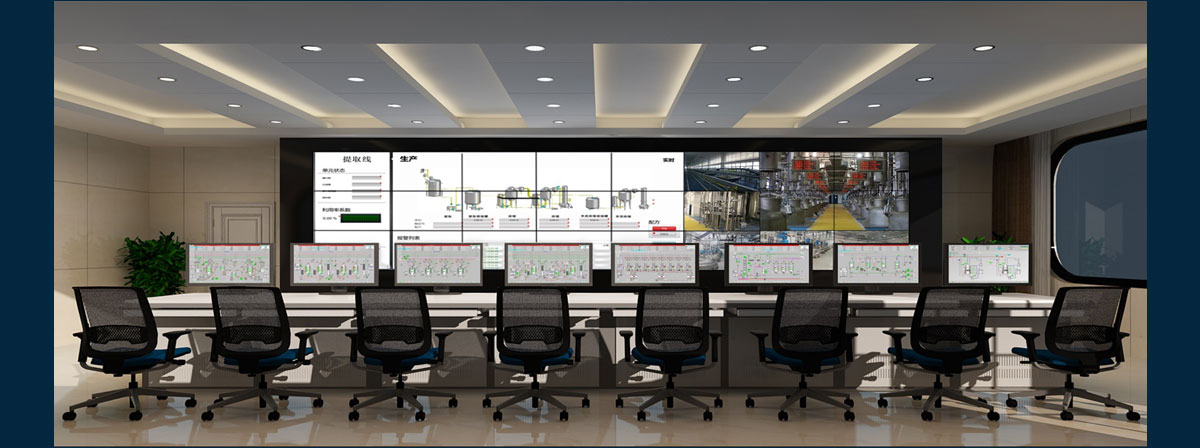

For the process sections of feeding, extraction, concentration, alcohol precipitation, online cleaning, etc., we design the control system network architecture, large screen comprehensive monitoring, and on-site process information display. We also design the process flow automation control, production control and process control scheme, and reflect the following main principles:

Economic

rationality

Modular design of

process units

Full quality

control

Computer System

Validation

【 Large screen comprehensive information display 】

【 Configuration screen 】

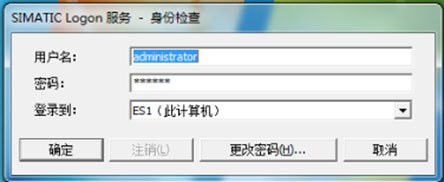

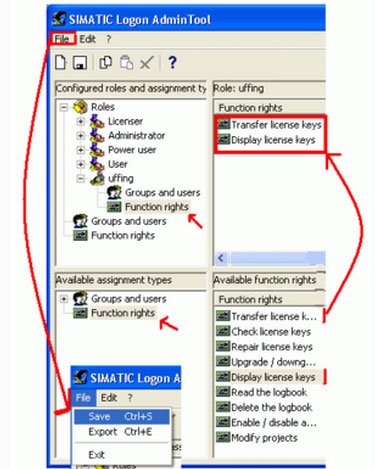

Process automation control authority management

Complex password policy

Password complexity requirements, password length limits, regular password changes, non-repetitive passwords, automatic account logout, account lockout, etc.

Multi-level permission allocation

Screen browsing, parameter input, modify alarm value, reset alarm, alarm confirmation, manual and automatic switching, operation mode selection, stop system, modify date and time, configuration, debugging, trend, edit security settings, edit user group data, edit user group access rights, change own password, etc.

【 System Cabinet 】

【 Communication valve island 】

【 Solenoid valve 】

【 Tracheal layout 】

【 Bridge cable tube 】

【 Automatic installation 】

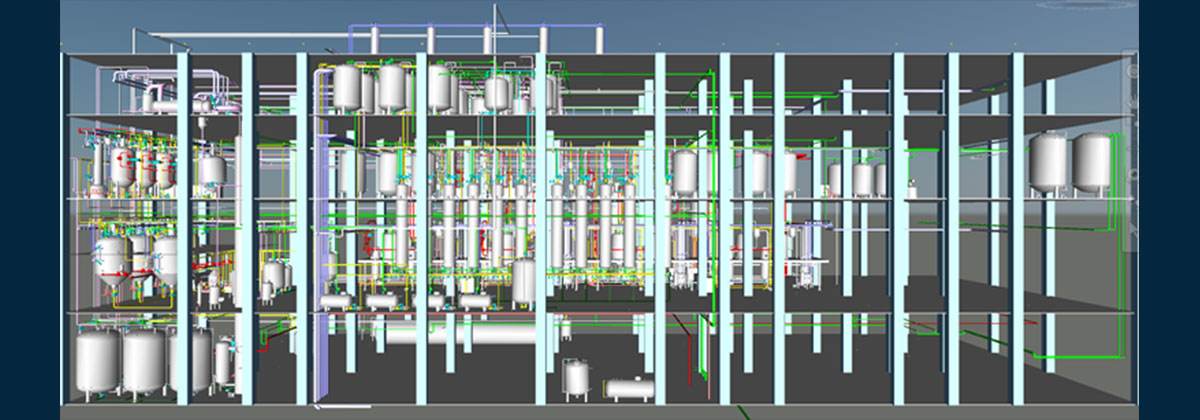

Factory 3D Design

3D Content:

3D drawing requirements:

Three-dimensional image function:

meter

Temperature Sensor

The temperature is measured using armored platinum resistance, with A-grade accuracy and made from domestic high-quality brands

Pressure transmitter

The pressure transmitter is a domestic high-quality brand with an accuracy of 0.5%

Liquid level transmitter

The capacitors are imported brands, with an accuracy of 5mm within 2m and 15mm above 2m

Flow transmitter

Electromagnetic flowmeter. Vortex flowmeter is imported brand

Density meter

Choose imported brands

Liquid level switch

Choose imported brands

valve

Steam Control Valve

Choose imported brands

Pneumatic diaphragm valve

Using domestic high-quality and imported brands

Pneumatic ball valve/pneumatic angle seat valve

Using domestic high-quality and imported brands

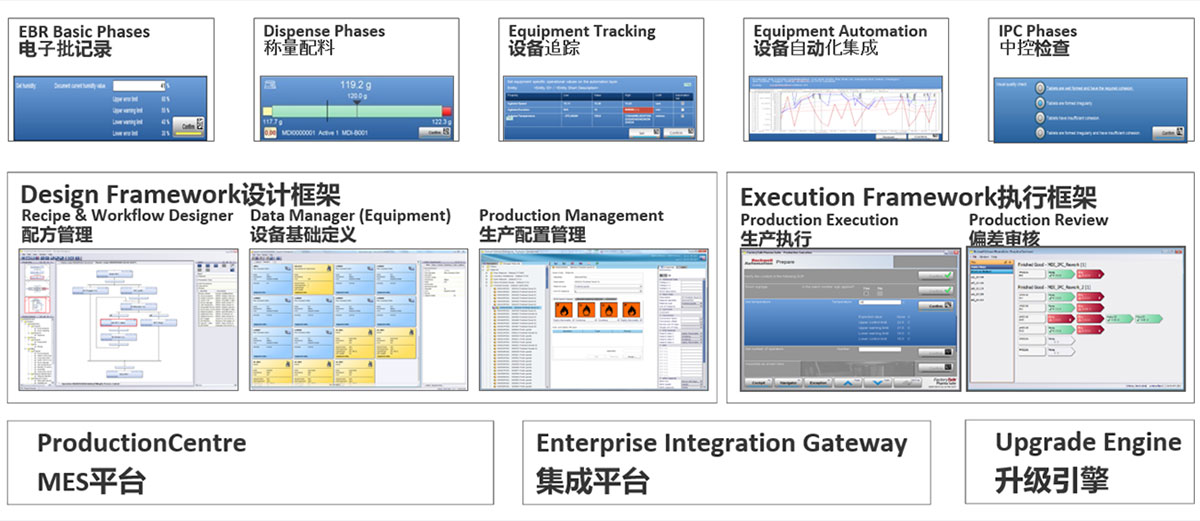

MES modular architecture

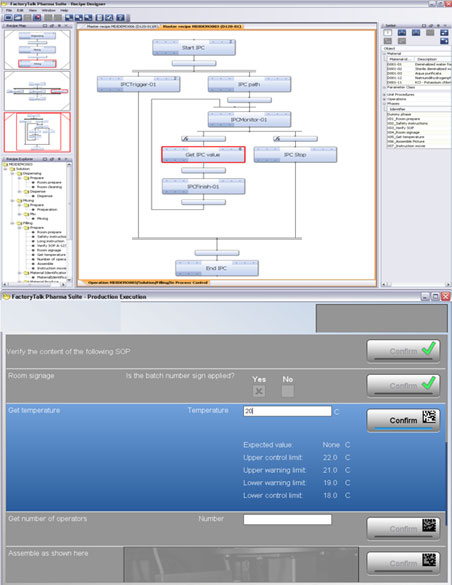

MES formula design and execution

Function Definition

Process recipe management

According to the product characteristics, the product process parameters are combined with the software formula management to realize the independent formula production, management and modification functions of each variety. At the same time, the automatic import and production of the formula can be realized, and the materials can be automatically identified. Automatic selection of formula parameters

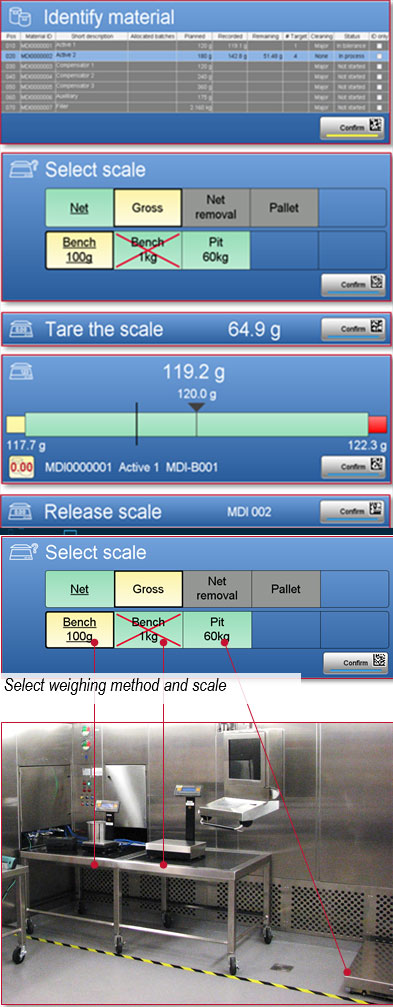

MES weighing ingredients

Role-Based Design

Easy to integrate

Open interface

Electronic scales

Deviation handling

Automatic control project case

【 Jiangsu Yangtze River (Longfengtang Phase I) Chinese medicine extraction digital workshop 】

【 Automation control of Chinese medicine extraction (Phase II) of Anhui Huarun Jinchan Pharmaceutical 】

JNBAN vacuum belt dryers have been included in the“ Eleventh Five-Year National Science and Technology Support Program, Zhejiang Science and Technology Department Major Science and Technology Public Relations Project and Zhejiang Province” Major Science and Technology Special (Priority Theme) Social Development Project. There are 4 papers and 6 patent applications accepted, including 4 invention patents, 2 special authorizations, and 10 practical patents. They won the third prize of Zhejiang Science and Technology Progress Award and the first set of products in Zhejiang Province.……

Wenzhou Jinbang Light Industry Machinery Co., Ltd. is a high-tech enterprise integrating R & D, manufacturing and sales. Professional in the production and sales of pharmaceutical, bioengineering machinery and equipment professional enterprises. The company mainly specializes in consulting, scheme design and manufacturing, budget, on-site installation and after-sale maintenance of traditional Chinese medicine extraction equipment, concentration equipment, separation and purification equipment, alcohol recovery equipment and drying equipment.……

Wenzhou Jinbang Light Ind Machinery Co., Ltd

E-mail: info@jnbantech.com

P.C: 325025

Address: No. 420 Binhai 23rd Road, Binhai Park, Economic & Technological Development Zone, Wenzhou, Zhejiang, China