The production process of yogurt involves several key steps. Here is a general outline of the process:

Milk Selection: High-quality milk is selected as the primary ingredient for yogurt production. The milk can come from various sources, such as cows, goats, or sheep.

Pasteurization: The milk is heated to a specific temperature (usually around 70-85°C) to kill any harmful bacteria present in the raw milk. This process helps to ensure the safety and shelf life of the yogurt.

After pasteurization, the milk is rapidly cooled to a temperature suitable for the fermentation process (usually around 40-45°C).

A small amount of starter culture, which consists of specific strains of lactic acid bacteria (such as Lactobacillus bulgaricus and Streptococcus thermophilus), is added to the cooled milk. The starter culture ferments lactose (milk sugar) into lactic acid, leading to the characteristic tangy flavor and thick texture of yogurt.

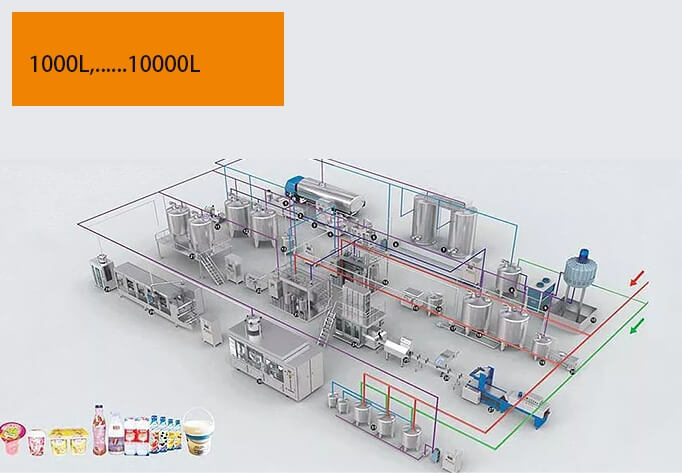

The milk with the starter culture is placed in a controlled environment, typically in large fermentation tanks or individual containers. The temperature is maintained around 40-45°C to promote the growth of the lactic acid bacteria. During this incubation period (usually 4-8 hours), the bacteria consume lactose and produce lactic acid, causing the milk to thicken and form a gel-like consistency.

After the desired fermentation time, additional ingredients such as fruit purees, sweeteners, or flavorings can be added to the yogurt to enhance its taste and variety. This step is optional and depends on the desired yogurt product.

The yogurt is cooled to stop the fermentation process and preserve its texture. It is then portioned into individual containers or bulk containers, depending on the packaging requirements. The containers are sealed and labeled for distribution.

The packaged yogurt is typically stored in refrigerated conditions to maintain freshness and extend shelf life.

JNBAN vacuum belt dryers have been included in the“ Eleventh Five-Year National Science and Technology Support Program, Zhejiang Science and Technology Department Major Science and Technology Public Relations Project and Zhejiang Province” Major Science and Technology Special (Priority Theme) Social Development Project. There are 4 papers and 6 patent applications accepted, including 4 invention patents, 2 special authorizations, and 10 practical patents. They won the third prize of Zhejiang Science and Technology Progress Award and the first set of products in Zhejiang Province.……

Wenzhou Jinbang Light Industry Machinery Co., Ltd. is a high-tech enterprise integrating R & D, manufacturing and sales. Professional in the production and sales of pharmaceutical, bioengineering machinery and equipment professional enterprises. The company mainly specializes in consulting, scheme design and manufacturing, budget, on-site installation and after-sale maintenance of traditional Chinese medicine extraction equipment, concentration equipment, separation and purification equipment, alcohol recovery equipment and drying equipment.……

Wenzhou Jinbang Light Ind Machinery Co., Ltd

E-mail: info@jnbantech.com

P.C: 325025

Address: No. 420 Binhai 23rd Road, Binhai Park, Economic & Technological Development Zone, Wenzhou, Zhejiang, China