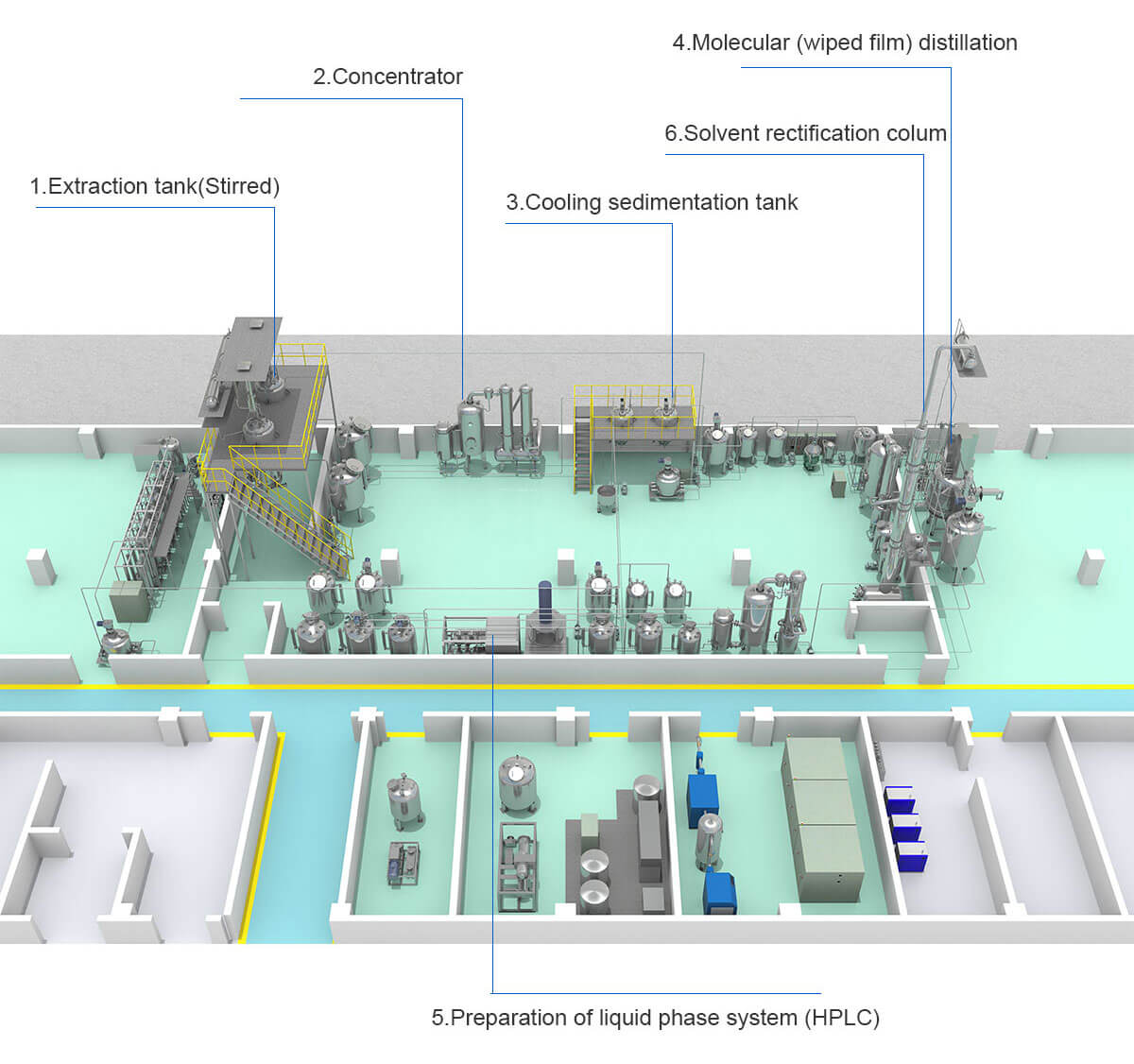

The production process of licorice extract typically involves several steps. Here is a general outline of the process:

Raw Material Selection: High-quality licorice roots are selected as the raw material for extraction. Licorice roots contain glycyrrhizin, the main active compound responsible for the sweet flavor and medicinal properties of licorice.

Cleaning and Washing: The licorice roots are thoroughly cleaned and washed to remove any dirt, debris, or impurities.

Cutting and Grinding: The cleaned licorice roots are cut into smaller pieces or ground into a coarse powder. This increases the surface area and facilitates the extraction process.

The cut or ground licorice roots are mixed with a suitable solvent, typically water or ethanol. The extraction process can be carried out through various methods, including maceration, percolation, or reflux extraction. The solvent helps to dissolve and extract the active compounds, including glycyrrhizin and other beneficial constituents.

Depending on the extraction method and desired purity, further purification steps may be employed. These can include techniques like precipitation, adsorption, or chromatography to isolate and purify specific compounds.

The filtered extract is concentrated to increase the concentration of active compounds. This can be achieved through methods like evaporation or vacuum distillation, which remove the solvent and concentrate the desired constituents.

The concentrated and purified extract is dried to remove any remaining moisture. This can be achieved through methods such as spray drying, freeze-drying, or vacuum drying. Drying helps to stabilize the extract and enhance its shelf life.

The tank is equipped with CIP cleaning automatic rotating spray ball, temperature gauge, pressure gauge, explosion-proof sightglass lamp, sight glass, quickopening feeding port, etc., to ensure easy operation and meet GMP standards. The inner cylinder of the equipment is made of 304 and 316L.

| Series technical parametes | TQ-1 | TQ-2 | TQ-3 | TQ-4 | TQ-5 | TQ-6 |

| Volume(L) | 1200 | 2300 | 3200 | 6300 | 8500 | 11000 |

| Tank design pressure (MPA) | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 |

| Compressed air pressure (MPA) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Feed port diameter (mm) | 400 | 400 | 400 | 500 | 500 | 500 |

| Heating area (m²) | 3 | 4.7 | 6 | 7.5 | 9.5 | 12 |

| Condensation area (m²) | 4 | 4 | 5 | 5 | 8 | 10 |

| Coling area (m²) | 1 | 1 | 1 | 2 | 2 | 3 |

| Filtration area (m²) | 3 | 3 | 3 | 5 | 5 | 6 |

| Slag gate area (m²) | 800 | 800 | 800 | 1000 | 1000 | 1000 |

| Energy consumption (kg/h) | 245 | 325 | 345 | 645 | 720 | 850 |

JNBAN vacuum belt dryers have been included in the“ Eleventh Five-Year National Science and Technology Support Program, Zhejiang Science and Technology Department Major Science and Technology Public Relations Project and Zhejiang Province” Major Science and Technology Special (Priority Theme) Social Development Project. There are 4 papers and 6 patent applications accepted, including 4 invention patents, 2 special authorizations, and 10 practical patents. They won the third prize of Zhejiang Science and Technology Progress Award and the first set of products in Zhejiang Province.……

Wenzhou Jinbang Light Industry Machinery Co., Ltd. is a high-tech enterprise integrating R & D, manufacturing and sales. Professional in the production and sales of pharmaceutical, bioengineering machinery and equipment professional enterprises. The company mainly specializes in consulting, scheme design and manufacturing, budget, on-site installation and after-sale maintenance of traditional Chinese medicine extraction equipment, concentration equipment, separation and purification equipment, alcohol recovery equipment and drying equipment.……

Wenzhou Jinbang Light Ind Machinery Co., Ltd

E-mail: info@jnbantech.com

P.C: 325025

Address: No. 420 Binhai 23rd Road, Binhai Park, Economic & Technological Development Zone, Wenzhou, Zhejiang, China