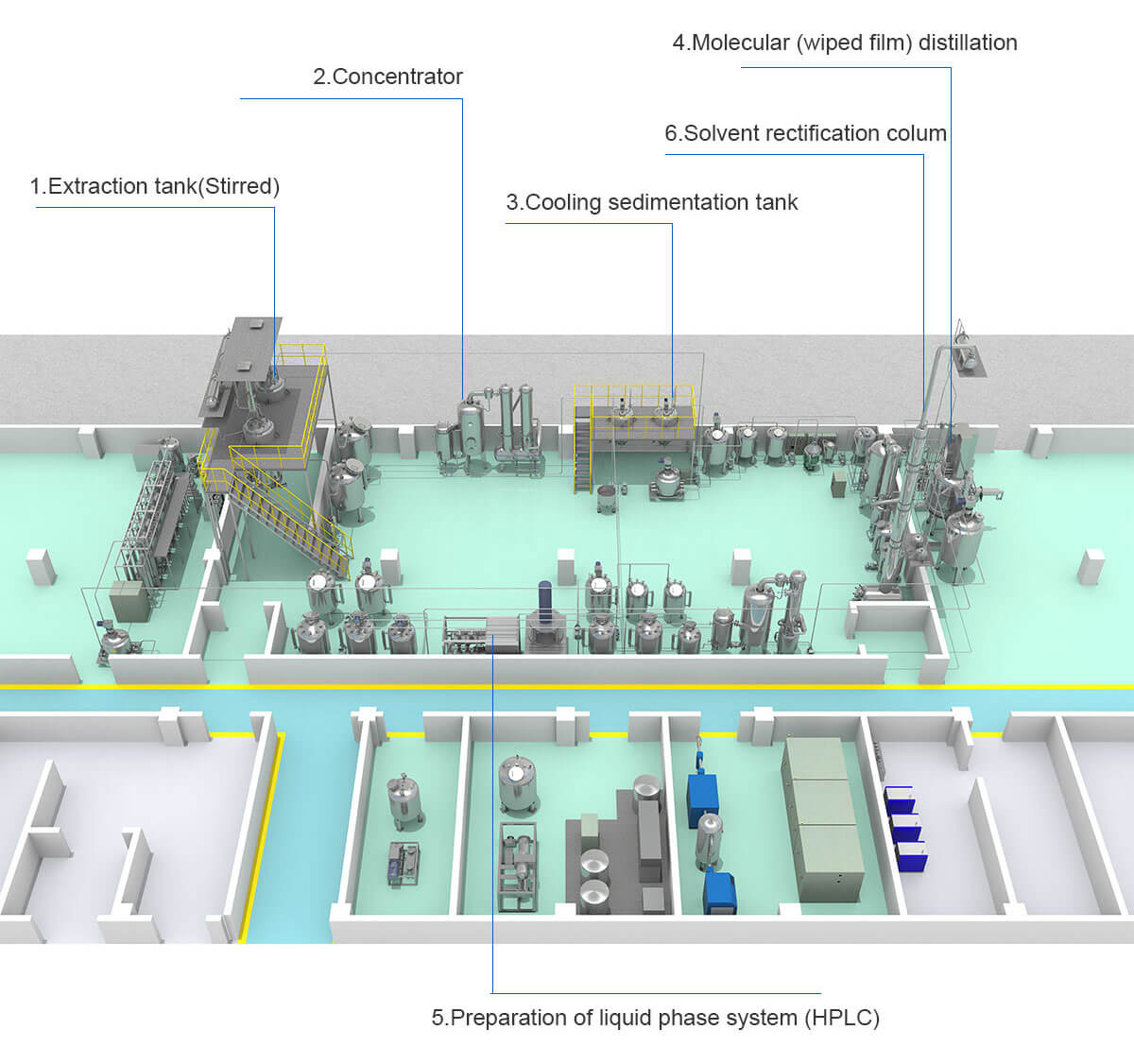

The production process of anthocyanins typically involves several steps. Here is a general outline of the process:

Source Selection: Anthocyanins can be obtained from various plant sources, such as berries, grapes, or flowers. The selection of the plant source depends on the desired type and quantity of anthocyanins.

Harvesting: The selected plant material is harvested at the appropriate stage of maturity to ensure optimal anthocyanin content.

The anthocyanins are extracted from the plant material using suitable solvents, such as water, ethanol, or a combination of both. The extraction method can vary, including techniques like maceration, percolation, or ultrasound-assisted extraction.

The crude extract obtained from the extraction process may contain impurities and other compounds. Purification methods, such as filtration, centrifugation, or chromatography, are employed to separate and isolate the anthocyanins.

The purified anthocyanin extract is concentrated to increase the concentration of the desired compounds. This can be achieved through techniques like evaporation, freeze-drying, or spray drying.

The concentrated anthocyanin extract is analyzed to determine its composition, purity, and other quality parameters. This may involve techniques such as spectrophotometry, high-performance liquid chromatography (HPLC), or mass spectrometry.

Depending on the intended application, the anthocyanins may be formulated into various products, such as powders, capsules, or liquid formulations. Stabilization methods, such as pH adjustment, addition of antioxidants, or encapsulation, may be employed to enhance the stability and shelf life of the anthocyanins.

The tank is equipped with CIP cleaning automatic rotating spray ball, temperature gauge, pressure gauge, explosion-proof sightglass lamp, sight glass, quickopening feeding port, etc., to ensure easy operation and meet GMP standards. The inner cylinder of the equipment is made of 304 and 316L.

| Series technical parametes | TQ-1 | TQ-2 | TQ-3 | TQ-4 | TQ-5 | TQ-6 |

| Volume(L) | 1200 | 2300 | 3200 | 6300 | 8500 | 11000 |

| Tank design pressure (MPA) | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 |

| Compressed air pressure (MPA) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Feed port diameter (mm) | 400 | 400 | 400 | 500 | 500 | 500 |

| Heating area (m²) | 3 | 4.7 | 6 | 7.5 | 9.5 | 12 |

| Condensation area (m²) | 4 | 4 | 5 | 5 | 8 | 10 |

| Coling area (m²) | 1 | 1 | 1 | 2 | 2 | 3 |

| Filtration area (m²) | 3 | 3 | 3 | 5 | 5 | 6 |

| Slag gate area (m²) | 800 | 800 | 800 | 1000 | 1000 | 1000 |

| Energy consumption (kg/h) | 245 | 325 | 345 | 645 | 720 | 850 |

JNBAN vacuum belt dryers have been included in the“ Eleventh Five-Year National Science and Technology Support Program, Zhejiang Science and Technology Department Major Science and Technology Public Relations Project and Zhejiang Province” Major Science and Technology Special (Priority Theme) Social Development Project. There are 4 papers and 6 patent applications accepted, including 4 invention patents, 2 special authorizations, and 10 practical patents. They won the third prize of Zhejiang Science and Technology Progress Award and the first set of products in Zhejiang Province.……

Wenzhou Jinbang Light Industry Machinery Co., Ltd. is a high-tech enterprise integrating R & D, manufacturing and sales. Professional in the production and sales of pharmaceutical, bioengineering machinery and equipment professional enterprises. The company mainly specializes in consulting, scheme design and manufacturing, budget, on-site installation and after-sale maintenance of traditional Chinese medicine extraction equipment, concentration equipment, separation and purification equipment, alcohol recovery equipment and drying equipment.……

Wenzhou Jinbang Light Ind Machinery Co., Ltd

E-mail: info@jnbantech.com

P.C: 325025

Address: No. 420 Binhai 23rd Road, Binhai Park, Economic & Technological Development Zone, Wenzhou, Zhejiang, China