ASME pressure vessels are widely used in the fields of petroleum, chemicals, rubber, pesticides, dyes, medicine and food. They are pressure vessels used to complete vulcanization, nitration, hydrogenation, hydrocarbonization, polymerization, condensation and other processes. Its structure generally consists of a kettle body, a transmission device, a stirring device, a heating device, a cooling device, a sealing device, a support, etc. Agitators include anchor type, frame type, paddle type, turbine type, scraper type, and combined type. Heating and cooling can use jackets, half pipes, coils, honeycomb panels and other structures. Heating methods include: steam, electric heating, and thermal oil. Supports include leg-type, ear-type and support-type supports to meet the process needs of different working environments such as acid resistance, high temperature resistance, wear resistance and corrosion resistance.

High strength and durability

ASME pressure vessels are made of stainless steel material, which has high strength and corrosion resistance. They are able to withstand working environments under high pressure and extreme conditions, ensuring stable and safe operation of industrial processes.

Diverse applications

ASME pressure vessels are widely used in various industries. They are used to store and transport gases, liquids or chemicals and provide essential products and services to the petroleum, chemical, energy, pharmaceutical and other industries. Whether storing liquefied gas, supplying industrial gases, or serving as nuclear reactor vessels in nuclear power plants, pressure vessels play an important role.

Space efficiency and energy conservation

ASME pressure vessels are typically designed to be compact, allowing efficient use of space. Compared with traditional storage methods, such as bulk storage, pressure vessels can save a lot of space and improve storage efficiency. In addition, ASME pressure vessels can reduce energy consumption and efficiently utilize heat energy.

In ASME (American Society of Mechanical Engineers), pressure vessel regulations are mainly defined by the ASME Boiler and Pressure Vessel Code (ASME Boiler and Pressure Vessel Code). According to this specification, a pressure vessel refers to a container used to store or transport gas, liquid or steam containing internal pressure.

JNBAN vacuum belt dryers have been included in the“ Eleventh Five-Year National Science and Technology Support Program, Zhejiang Science and Technology Department Major Science and Technology Public Relations Project and Zhejiang Province” Major Science and Technology Special (Priority Theme) Social Development Project. There are 4 papers and 6 patent applications accepted, including 4 invention patents, 2 special authorizations, and 10 practical patents. They won the third prize of Zhejiang Science and Technology Progress Award and the first set of products in Zhejiang Province.……

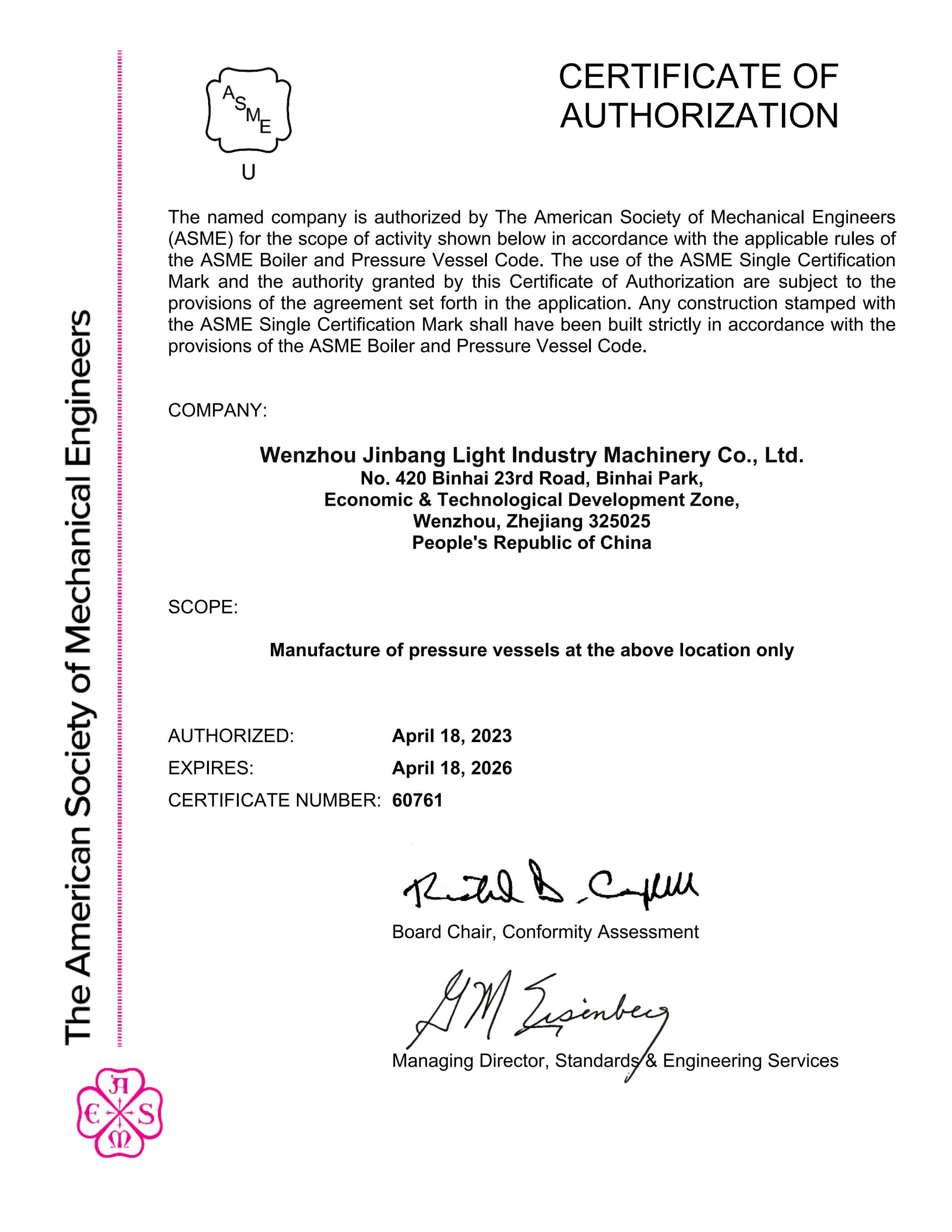

Wenzhou Jinbang Light Industry Machinery Co., Ltd. is a high-tech enterprise integrating R & D, manufacturing and sales. Professional in the production and sales of pharmaceutical, bioengineering machinery and equipment professional enterprises. The company mainly specializes in consulting, scheme design and manufacturing, budget, on-site installation and after-sale maintenance of traditional Chinese medicine extraction equipment, concentration equipment, separation and purification equipment, alcohol recovery equipment and drying equipment.……

Wenzhou Jinbang Light Ind Machinery Co., Ltd

E-mail: info@jnbantech.com

P.C: 325025

Address: No. 420 Binhai 23rd Road, Binhai Park, Economic & Technological Development Zone, Wenzhou, Zhejiang, China