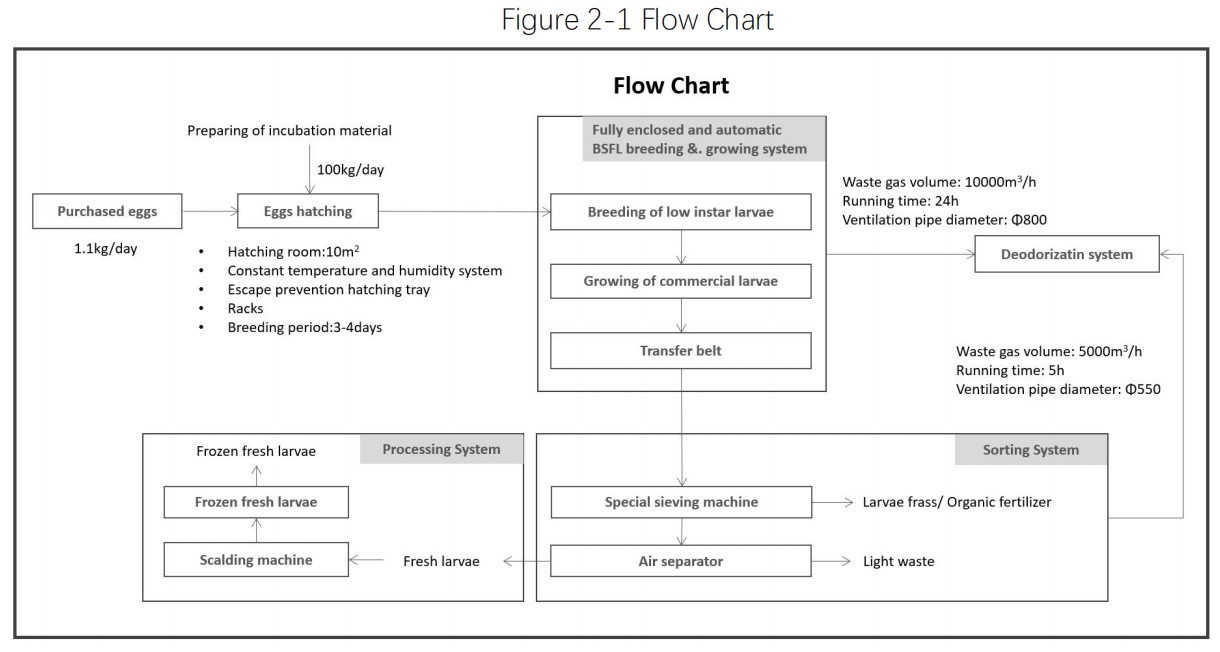

The design boundary starts from the sorted kitchen waste which obtained 25% organic solid slag and 75% moisture, and after crushing and pulping. The whole process includes 5 parts: egg hatching, low instar larvae breeding(cultivation), automatic larvae growing, larvae sorting, processing, and deodorization.

Process time: 3 days from more than 85% of the eggs hatched. Standard: the BSF larvae grows to the size of 2~3mm, and the body is fresh and full. Feed: chicken / piglet feed, fermentation bacteria, vitamins, calcium propionate, fermented for 1-2 days. Materials: incubator tray, oil paper, spray can, brush, temperature and hygrometer. Note:

| Name | Specification | Power/Kw | Amount | Remark |

| 1. Constant temperature and humidity system | 10 ㎡ room space, air conditioner, humidifier, radiator, etc.. | 5 | 1 | Intelligent control |

| 2. Incubation trays | W84cm×L206cm×H15cm | 0 | 66 | 201 stainless steel |

| 3. Racks | 8 layers * 2 columns | 0 | 5 | Customization |

Process period: the low instar larvae were bred for 6 days, and the commercial larvae were grown for another 6 days.

The standard of low instar larvae: body length 8-10 mm, after removing frass and separatepacking, it will enter the process of commercial larvae cultivation phase.

The standard of commercial larvae: body length 2 cm, black larvae≤3%.

Production efficiency: an average of 2 minutes per tray, consumption of 80 – 100KG of solid residue, production of 15 -20KG fresh BSFL (depending on raw materials).

Area efficiency: the automatic growing system can realize 12 layers high density culture within the height of 5 meters. Culture area / land area > 5.

Automatic BSFL growing system includes growing line, lift & transfer mechanism, feeding mechanism, harvest mechanism, environment control system and PLC automatic control system.

Every feeding can cover 5 – 6 days culture period, and be able to realize multi-feeding for the supplement. A high degree of automation, after setting the parameters, the system will operate automatically.

Method 1: greenhouse film sealing, low cost, lack of beauty.

Method 2: sandwich rock wool board sealing, high cost, strong and neat.

JNBAN vacuum belt dryers have been included in the“ Eleventh Five-Year National Science and Technology Support Program, Zhejiang Science and Technology Department Major Science and Technology Public Relations Project and Zhejiang Province” Major Science and Technology Special (Priority Theme) Social Development Project. There are 4 papers and 6 patent applications accepted, including 4 invention patents, 2 special authorizations, and 10 practical patents. They won the third prize of Zhejiang Science and Technology Progress Award and the first set of products in Zhejiang Province.……

Wenzhou Jinbang Light Industry Machinery Co., Ltd. is a high-tech enterprise integrating R & D, manufacturing and sales. Professional in the production and sales of pharmaceutical, bioengineering machinery and equipment professional enterprises. The company mainly specializes in consulting, scheme design and manufacturing, budget, on-site installation and after-sale maintenance of traditional Chinese medicine extraction equipment, concentration equipment, separation and purification equipment, alcohol recovery equipment and drying equipment.……

Wenzhou Jinbang Light Ind Machinery Co., Ltd

E-mail: info@jnbantech.com

P.C: 325025

Address: No. 420 Binhai 23rd Road, Binhai Park, Economic & Technological Development Zone, Wenzhou, Zhejiang, China