2024-07-26

If you have any questions about Falling Film Evaporator, please feel free to contact me. Tel/WeChat/Whatsapp: +86-13819752271 Mr. Siman

What is a Falling Film Evaporator?

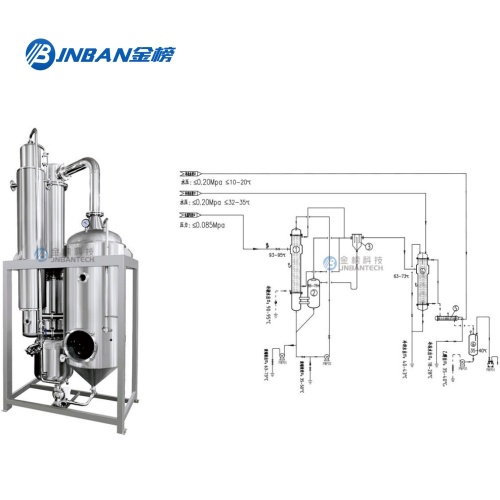

A falling film evaporator is a specialized type of heat exchanger that efficiently concentrates solutions by evaporating the solvent, typically water, from a thin film of liquid. This process occurs on the surface of vertical tubes or plates, where the liquid flows downward under the influence of gravity. The evaporator operates under low-temperature conditions, minimizing thermal degradation of heat-sensitive materials.

Key Components and Working Principle

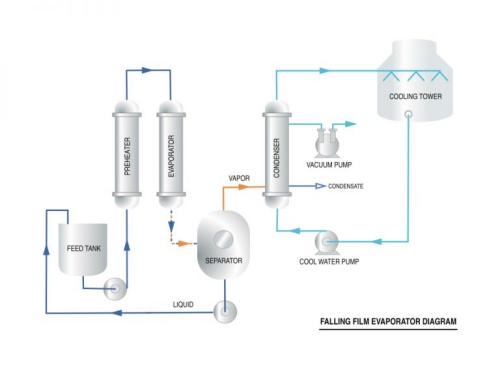

The primary components of a falling film evaporator include:

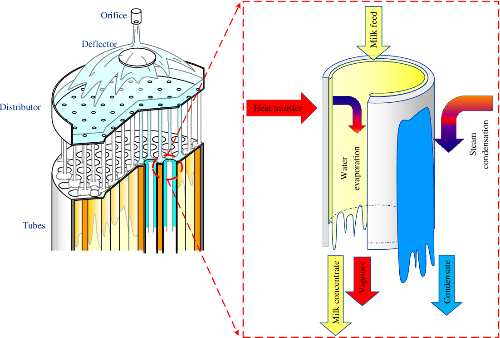

- **Heating Tubes or Plates**: These provide the surface on which the liquid film forms and evaporates.

- **Distributor**: Ensures even distribution of the liquid onto the heating surface.

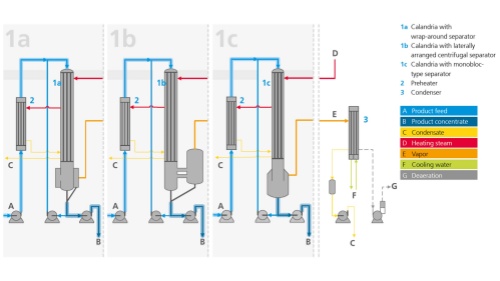

- **Vapor Separator**: Separates the vapor from the concentrated liquid.

- **Condenser**: Condenses the vapor into a liquid form for collection or further processing.

The working principle involves feeding the liquid at the top of the evaporator, where it is evenly distributed onto the heating surfaces. As the liquid flows down, it forms a thin film and is heated by the steam or hot water within the tubes or plates. This causes the solvent to evaporate, leaving behind a more concentrated solution. The vapor is then separated and condensed for collection.

Advantages of Falling Film Evaporators

1. **High Efficiency**: Falling film evaporators offer excellent heat transfer efficiency due to the thin liquid film, which facilitates rapid evaporation.

2. **Low Operating Temperatures**: They operate at low temperatures, making them ideal for heat-sensitive materials and reducing the risk of thermal degradation.

3. **Energy Savings**: These evaporators require less energy compared to other types of evaporators, contributing to lower operational costs.

4. **Flexibility**: Falling film evaporators can handle a wide range of viscosities and are suitable for concentrating heat-sensitive and non-heat-sensitive liquids alike.

5. **Scalability**: They are available in various sizes, making them suitable for both small-scale and large-scale industrial applications.

Applications of Falling Film Evaporators

Falling film evaporators are used in diverse industries for various applications, including:

- **Food and Beverage**: Concentration of fruit juices, milk, and other dairy products while preserving flavor and nutritional content.

- **Chemical**: Concentration of chemical solutions, removal of solvents, and recovery of valuable compounds.

- **Pharmaceutical**: Concentration of active pharmaceutical ingredients (APIs) and other heat-sensitive compounds.

- **Environmental**: Treatment of wastewater and recovery of valuable materials from effluents.

- **Renewable Energy**: Concentration of biofuels and other renewable energy sources.

Conclusion

Falling film evaporators are a vital component in modern industrial processes, offering unparalleled efficiency and versatility. As a manufacturer, we are dedicated to providing high-quality falling film evaporators that meet the specific needs of our clients. Our expertise and commitment to innovation ensure that our products deliver optimal performance and reliability.

For more information on our falling film evaporators and how they can benefit your operations, please contact us today. Our team of experts is ready to assist you in finding the perfect solution for your application.

For detailed equipment parameters, please click on the link:Falling Film Evaporator